VL-25

Specifically Designed for Large and Heavy-Duty Workpiece.Capable of cutting diameter up to 3000mm

specification

| Max turning diameter | mm | Ø3000 |

| Max turning height | mm | 1060 |

| Max torque | N-m | 15553 |

| Size | mm | Ø 2700 |

| Table load | kg | 20000 |

| Table rotation | rpm | 1.6~160 |

| Motor | α40, 6000i | |

| Motor(cont/30 mins) | kW | 37/45 |

| X axis stroke(Horizontal)(RAM) | mm | 2100 |

| Z axis stroke(Vertical)(RAM) | mm | 1060 |

| X axis feed rate(RAM) | mm/min | 0-8000 |

| Z axis feed rate(RAM) | mm/min | 0-8000 |

| Z axis stroke(Vertical)(Cross rail) | mm | 1300 |

| Rapid of cross rail | mm/min | 400 |

| Tool number | 8holders, BT50 | |

| Shank size | mm | □32(□25), Ø32/Ø40/Ø50 |

| Table | kW | AC 37/45 |

| Cross rail | kW | AC 5.5 |

| Hydraulic power | kW | AC 3.7 |

| Table lubricating | kW | AC 0.37 |

| Slide lubricating | kW | AC 0.025 (2 set) |

| X axis | kW | α30i |

| Z axis | kW | α40iB |

| Floor space (L xW x H) |

mm | 6250x4590x6300 |

| Machine weight | kg | 30000 |

| Total power rating | KVA | 80 |

| Controller system | FANUC 0i-T | |

| Positioning accuracy X/Z | mm/M | 0.03 |

| Repeatability X/Z | mm/M | 0.015 |

FEATURES

Double Precision Positioned Rack

The one-piece grinding dual racks ensure the flatness between the two positioning hooks of the crossrail and the engaging surfaces of the racks and provide the levelness required by the crossrail.

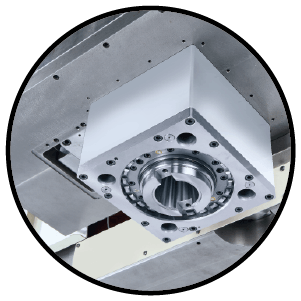

Closed-Loop Feedback Control structure

To avoid the influence due to temperature difference or the rigidity of the transmission system, linear scales for X-axis and Z-axis can be adopted to build up closed-loop feedback control, which ensures the stability of processing accuracy for a long operating.

Crossrail Positioning Hooks and

Mechanical Anti Fall-off Device

When the hooks are positioned, the anti-fall off device is also compulsively activated without any interference from a loss of power to secure the positioning accuracy of the Crossrail.

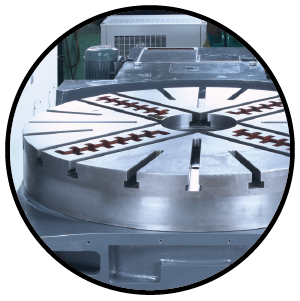

WORKTABLE WITH HIGH lOADING CAPACITY

The maximum allowable load of the worktable is 20 tons with a diameter of 2,700mm

Crossrail

Made by Meehanite cast iron Crossrail, the surface of guideways is heat-treated for hardness and tensile strength. The saddle is treated with Turcite-B for smooth and precise movement.

High Rigidity Dual Vertical

Columns

The columns are constructed of box structure, which has extremely high rigidity, to form a door-shape structure with left and right columns. They can improve the accuracy and rigidity during milling.