VL-25M

Double-Column Structures, with High Performance, & High Stability.Exclusive unique rotational turret achieves inner and outer diametrical turning fast and efficient.

specification

| Max turning diameter | mm | Ø3000 |

| Max turning height | mm | 1800 |

| Max torque | N-m | 32200 |

| Size | mm | Ø 2700 |

| Table load | kg | 20000 |

| Table rotation | rpm | 1.6~160 |

| Motor | α40, 6000i | |

| Motor(cont/30 mins) | kW | 37/45 |

| X axis stroke(Horizontal)(RAM) | mm | 2100 |

| Z axis stroke(Vertical)(RAM) | mm | 1200 |

| X axis feed rate(RAM) | mm/min | 0-8000 |

| Z axis feed rate(RAM) | mm/min | 0-20000 |

| Z axis stroke(Vertical)(Cross rail) | mm | 1500 |

| Rapid of cross rail | mm/min | 400 |

| Tool number | 1cover+5turning+6milling, ISO50 | |

| Shank size | mm | □32, Ø32/Ø40/Ø50 |

| Table | kW | AC 37/45 |

| Cross rail | kW | AC 5.5 |

| Hydraulic power | kW | AC 3.7 |

| Table lubricating | kW | AC 0.37 |

| Slide lubricating | kW | AC 0.025 (2 set) |

| X axis | kW | α30i |

| Z axis | kW | α40iB |

| Power spindle | kW | 15/18.5 |

| Floor space(L xW x H) | mm | 62500x4696x6410 |

| Machine weight | kg | 30000 |

| Total power rating | KVA | 95 |

| Controller system | mm | FANUC 0i-T |

| Positioning accuracy X/Z | mm/M | 0.03 |

| Positioning accuracy C | ±7.5″/360° | |

| Repeatability X/Z(C) | mm/M | 0.015(±5″) |

FEATURES

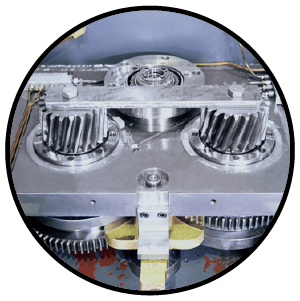

Unique drive Mechanism of

Worktable

The patented design of worktable’s drive mechanism delivers the elimination of backlash by PLC system. Using single motor to drive the table saves the time-switching between turning and milling processing.

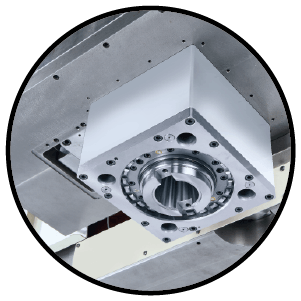

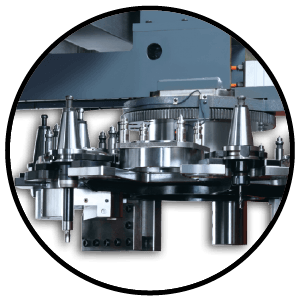

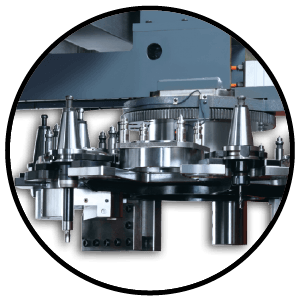

Unique RAM Exchange

Interface Design

The RAM has three special features. First, the unique interface design enables automatic tools exchange. Second, the built-in power tools provide milling function.

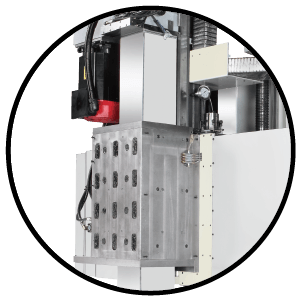

Fully Covered Saddle

This model features a fully enclosed

hydrostatic system with artificial granite casting. This reduces vibration during operation and increases precision and cutting efficiency while machining.

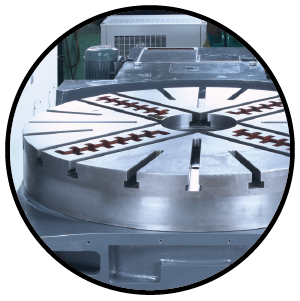

Worktable with high loading capacity

The maximum allowable load of the

worktable is 20 tons with a diameter of 2,700mm and it utilizes high-rigidity, high-precision crossed roller bearing with proper preload that is capable of resisting cutting load from all directions.

TOOL STATION

Tool stations have the capacity for 6 positions (right-angle milling head and turning tool head) and 12 positions (power tool head). Combining with RAM can achieve auto tool change function.

High Rigidity Dual Vertical Columns

The columns are constructed of box

structure, which has extremely high rigidity, to form a door-shape structure with left and right columns. They can improve the accuracy and the rigidity during milling.

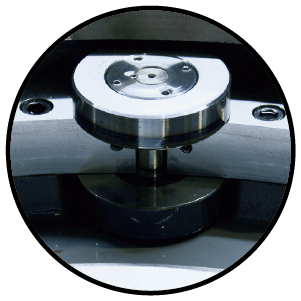

Brake Clamping Mechanism

The float-type brake mechanism will not influence the position accuracy of the worktable when clamping and its clamping function will not be influenced by temperature rise.

RAM

The dimensions of square cross-sectional ram are 230mmx230mm with Z-axis travel of 1,200mm. With the vertically moving Crossrail, the ram can perform all kinds of deep hole boring.